Plc High Cpu Usage – A Detailed Overview!

High CPU usage in a PLC often stems from complex programming, communication load, or hardware limits. Optimizing code and upgrading hardware reduces strain.

Table of Contents

What Causes High CPU Usage in a PLC?

High CPU usage in a PLC can be triggered by several factors, including program complexity, inefficient code, and increased communication load. Each of these factors plays a role in taxing the PLC’s resources, leading to higher-than-normal CPU utilization.

1. Complex or Inefficient Code:

- Overly Complicated Logic: The more complex the programming logic, the harder the CPU works to execute commands. Inefficient or redundant code can significantly add to the CPU workload.

- Unoptimized Code: Poorly optimized code, such as nested loops and unnecessary calculations, can also increase CPU usage. Proper code structuring, efficient data handling, and minimizing repetitive calculations can help.

2. Frequent Communication Requests:

- High Data Exchange: If the PLC is constantly sending and receiving data from other devices, this can burden the CPU. Increased traffic on the network can lead to spikes in CPU usage, especially if data processing is extensive.

- Multiple Connections: Establishing many concurrent communication links with other systems or devices can create bottlenecks, resulting in the CPU dedicating more resources to manage the communications.

3. Insufficient Hardware Capabilities:

- CPU Power Limitations: A PLC’s CPU has finite processing power. Complex applications or an expanding automation system may exceed the CPU’s capabilities, causing high usage.

- Memory Constraints: If a PLC’s memory becomes overloaded, the CPU compensates by allocating more processing power, further increasing CPU usage.

4. Continuous Program Execution:

- High Execution Rates: Some applications require continuous or high-frequency execution of certain routines, which can increase the CPU’s workload. Even small, frequently-run tasks can accumulate CPU load over time.

Effects of High CPU Usage in PLCs:

High CPU usage in a PLC can have several detrimental effects on an industrial system. Understanding these potential issues is essential to preventing operational disruptions.

1. System Delays and Slower Processing:

When CPU usage is high, processing speeds may decrease, leading to delays in executing essential tasks. This can slow down the entire system, causing a noticeable impact on overall productivity and efficiency.

2. Reduced Response Time:

PLCs operating with high CPU usage may struggle to respond promptly to input signals, leading to delays in real-time operations. In time-sensitive processes, such delays can create issues or even compromise safety.

Also Read: How To Determne A Pnoz Multi Cpu Ip Address – A Step-by-Step Guide!

3. Unexpected System Shutdowns or Crashes:

If CPU usage continues unchecked, it may cause the PLC to overheat or exceed its operational limits, leading to unexpected shutdowns or crashes. This can result in costly downtime and possible damage to equipment or processes.

4. Increased Maintenance Needs:

Constantly running at high CPU usage accelerates wear on the PLC components, potentially increasing the need for maintenance and reducing the system’s lifespan. It may also signal the need to upgrade to more powerful hardware.

How to Reduce High CPU Usage in PLCs:

Thankfully, there are several ways to manage and reduce high CPU usage in PLCs. A few proactive measures can help optimize performance and improve the longevity of the PLC system.

Optimize PLC Code:

- Streamline Logic: Simplify the code wherever possible. Break down complex logic into simpler, smaller routines that the CPU can handle more efficiently.

- Avoid Redundant Calculations: Remove any repetitive calculations or nested loops within the code. Use more efficient data structures to minimize CPU demand.

- Use Conditional Scanning: Instead of executing all instructions continuously, configure the PLC to execute specific instructions only when necessary. This can significantly reduce CPU load.

Reduce Communication Load:

- Optimize Data Transfer: Reduce the amount of data being sent and received by adjusting data packet sizes or frequency. Compress data when possible to lower transmission requirements.

- Limit Simultaneous Connections: Try to minimize the number of devices the PLC communicates with simultaneously. Utilize gateways or intermediary devices to reduce direct connections to the PLC.

Upgrade Hardware or Add a Secondary CPU:

- Upgrade to a Higher-Capacity PLC: If your PLC’s CPU cannot handle the required workload, upgrading to a model with higher processing power might be a good investment.

- Implement Distributed Control Systems (DCS): For large systems, dividing tasks among several PLCs can spread the CPU load, helping each PLC operate more efficiently and with less strain.

Use Timed Execution Intervals:

- Adjust Scan Rates: Adjust the frequency at which the PLC executes certain tasks. Tasks that don’t need to be performed as frequently can be scheduled at longer intervals to conserve CPU resources.

- Prioritize Tasks: Set lower priorities for non-critical tasks, allowing the CPU to focus on essential functions without unnecessary strain.

Monitoring and Preventing High CPU Usage:

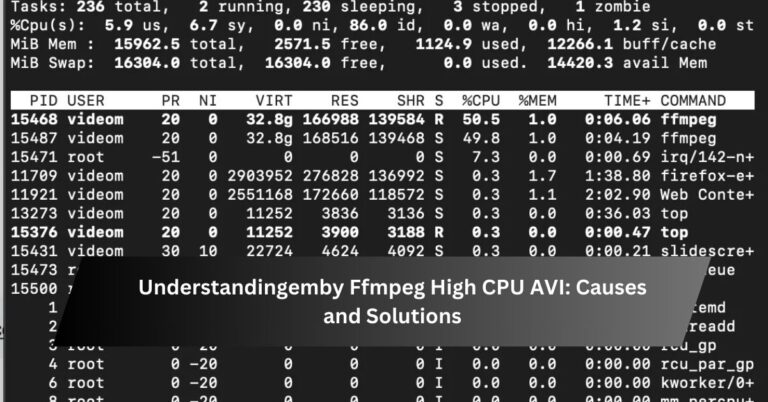

Consistently monitoring CPU usage can help prevent issues before they escalate. Many PLCs offer built-in diagnostic tools that allow operators to monitor CPU usage in real time. Using this data, operators can proactively make changes to prevent high CPU usage. Here’s how:

- Use Diagnostic Tools: Regularly check diagnostic tools to monitor CPU load. If a CPU is consistently operating at high capacity, consider optimizing code or reducing tasks.

- Plan Maintenance: Schedule regular PLC maintenance and code reviews to ensure that system resources are managed efficiently.

- Set Alerts: Configure alarms or alerts within the system that trigger when CPU usage exceeds a specified threshold, so that operators can investigate and address issues before they cause downtime.

FAQ’s

1. What causes high CPU usage in a PLC?

High CPU usage can result from complex or inefficient code, frequent communication requests, insufficient hardware, or continuous program execution demands.

2. What are the effects of high CPU usage in a PLC?

High CPU usage can lead to system delays, reduced response times, unexpected shutdowns, and increased maintenance needs.

3. How can I reduce high CPU usage in a PLC?

Reducing high CPU usage involves optimizing code, reducing communication loads, upgrading hardware, and using timed execution intervals for tasks.

4. Why does inefficient code increase PLC CPU usage?

Inefficient code with redundant calculations and complex logic requires more processing power, causing the CPU to work harder than necessary.

5. What tools help monitor and prevent high CPU usage in PLCs?

Diagnostic tools in PLCs allow real-time CPU monitoring, and setting alerts can help operators proactively manage CPU load before issues escalate.

Final Thoughts

High CPU usage in PLCs can hinder productivity, slow response times, and even cause system failures. By understanding the root causes, potential impacts, and preventive measures, operators can optimize their PLCs, ensuring smooth and reliable operation. Whether through code optimization, managing communication loads, or upgrading hardware, managing CPU usage effectively can help maintain a reliable, efficient automation system, supporting the operational goals of any industry.