High Cpu Plc Usage – A Comprehensive Overview!

High CPU usage in PLCs leads to inefficiencies, delays, and potential system failures. Addressing its causes ensures efficient, reliable automation performance.

Here, we explore what high CPU usage in PLCs entails, its common causes, effects on systems, and practical solutions to keep things running efficiently.

Table of Contents

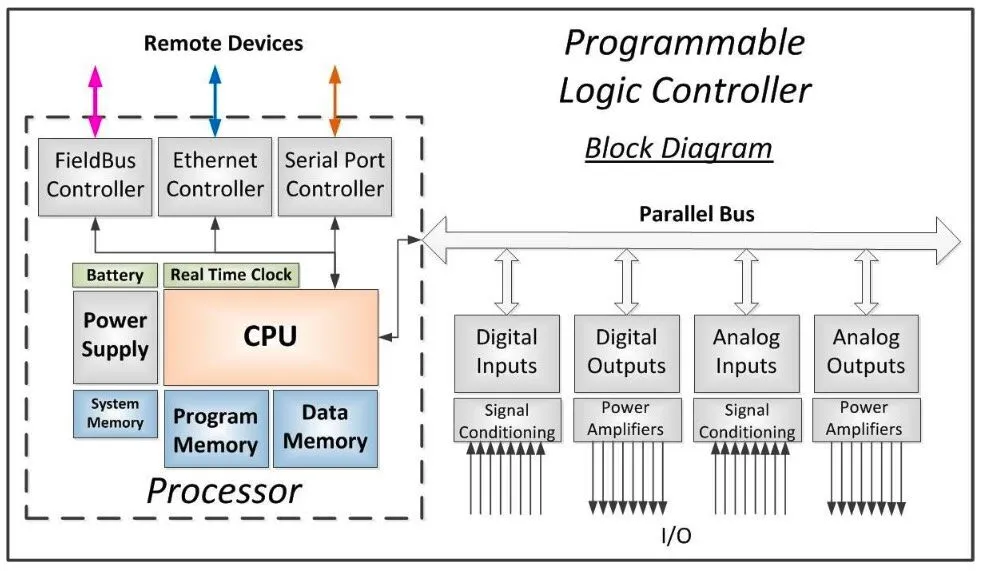

What is High CPU Usage in a PLC?

High CPU usage in a PLC refers to the processor’s workload nearing or reaching maximum capacity during its operations. When the CPU usage consistently runs high, it indicates that the PLC is struggling to handle its programming logic and tasks efficiently. Just as with computers, a PLC’s high CPU usage can be problematic, potentially causing delays or downtime in automated processes.

Common Causes of High CPU Usage in PLCs:

Understanding the reasons behind high CPU usage in a PLC is the first step to finding a solution. Here are some of the primary causes:

Complex Programming Logic:

PLCs handle programming instructions that control everything from simple motor on/off tasks to complex motion control. When a PLC program has extensive or highly intricate logic, the CPU may become overloaded. Overuse of nested loops, complex mathematical calculations, or excessive conditional statements can quickly elevate CPU usage.

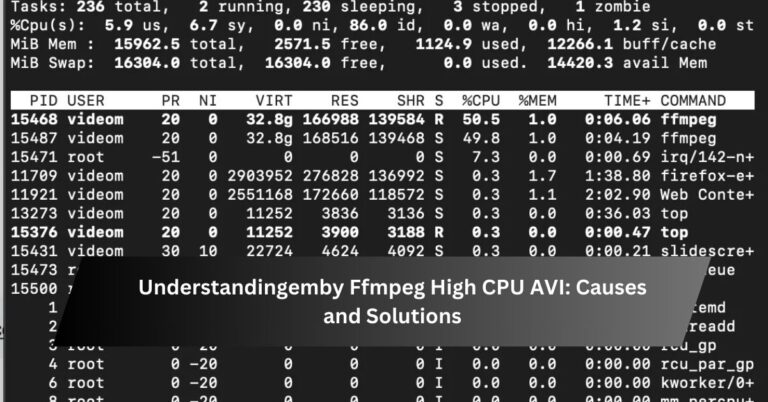

High-Speed Data Processing:

Modern PLCs often handle high-speed data, especially in systems where data must be processed and logged quickly. In such cases, the CPU may be constantly working to process incoming data, contributing to high CPU usage.

Frequent Interrupts and I/O Operations:

PLCs are tasked with handling inputs and outputs, responding to sensors, and managing controls. Frequent interrupt signals or a high volume of I/O tasks can strain the CPU, especially if the device isn’t optimized for high-speed or high-frequency input/output processing.

High Data Logging Requirements:

Data logging in PLCs, often used for monitoring and analysis, can contribute to CPU overload if logging is continuous or performed at very high frequencies. In such cases, the PLC CPU spends a lot of time recording data rather than executing operational logic.

Poorly Optimized Code:

Code that isn’t optimized for efficiency can lead to higher CPU usage. Inefficient programming practices, such as unnecessary computations, unoptimized looping, or failing to use appropriate commands, can burden the CPU.

Excessive Communication Tasks:

PLCs often communicate with other devices, like Human Machine Interfaces (HMIs) or other PLCs, over protocols such as Modbus, EtherNet/IP, or PROFINET. If communication cycles are excessive or not managed well, the PLC CPU may struggle to keep up.

Effects of High CPU Usage in PLCs:

High CPU usage in PLCs can lead to several operational issues:

- Reduced Processing Speed: A high CPU load may cause the PLC to process commands and logic more slowly, leading to potential delays.

- System Crashes or Freezes: Consistent high CPU usage may cause the PLC to freeze, interrupting automated processes and potentially damaging machinery or products.

- Poor Response Times: High CPU usage can lead to delayed responses, which can disrupt timing-critical operations, such as motion control tasks.

- Increased Power Consumption: High CPU usage can lead to increased power draw, which can reduce overall system efficiency and raise energy costs.

- Shortened PLC Lifespan: A continuously overburdened CPU may shorten the lifespan of the PLC, increasing the need for repairs or replacements.

Solutions to Reduce High CPU Usage in PLCs:

Addressing high CPU usage in PLCs involves various strategies to improve program efficiency and optimize system performance:

- Optimize Program Logic: Simplify complex logic, avoid excessive nesting of loops, and eliminate unnecessary calculations. This helps streamline operations, allowing the CPU to process commands more efficiently.

- Implement Task Prioritization: Prioritize tasks to ensure that time-sensitive processes are handled first. Most PLCs allow tasks to be assigned as high-priority or low-priority, allowing the CPU to manage its resources better.

- Adjust Data Logging Frequencies: If possible, reduce the frequency of data logging to decrease the strain on the CPU. Analyze what data is necessary and consider storing less essential data in lower frequency intervals.

- Improve I/O Management: Review I/O operations and assess if they can be optimized. Reducing the frequency or quantity of inputs and outputs processed per cycle can decrease CPU load significantly.

- Use Efficient Communication Protocols: If the PLC is communicating with multiple devices, ensure efficient protocols are in place. Avoid unnecessary communication cycles by using only required data exchange intervals and methods.

- Monitor and Upgrade Hardware: Regularly monitor CPU usage and consider upgrading to a PLC with a higher processing capacity if CPU usage consistently remains high. Newer PLCs often feature optimized CPUs that can handle more complex and frequent tasks efficiently.

- Limit Use of Interrupts: Minimize the use of interrupts, especially for non-critical functions. Excessive interrupts force the CPU to shift focus, causing higher usage. Grouping non-urgent interrupts can help reduce unnecessary load.

- Utilize Task Scheduling Features: Some PLCs offer advanced scheduling features that allow tasks to run at specified intervals. Use these features to control CPU demand, reserving the processor for essential tasks at critical times.

Best Practices to Prevent High CPU Usage in PLCs:

- Regularly Update Firmware: Ensure the PLC firmware is up-to-date, as manufacturers often release updates that improve CPU efficiency and address performance issues.

- Use Diagnostic Tools: Many PLCs come with built-in diagnostic tools that can monitor CPU usage. Regular checks can help identify spikes in CPU load and allow preventive action.

- Document and Review Code Regularly: Regularly review and document your code, refining sections that could be optimized. This practice can reveal inefficiencies that may contribute to high CPU usage.

- Train Staff on Efficient Programming: Proper training on best programming practices can prevent the development of inefficient code, ensuring that the PLC is used optimally from the start.

FAQ’s

1. What causes high CPU usage in a PLC?

High CPU usage is often due to complex programming logic, high-speed data processing, frequent interrupts, and inefficient code.

2. What are the effects of high CPU usage on PLC systems?

It can slow processing, lead to system crashes, reduce response times, increase power consumption, and shorten the PLC’s lifespan.

3. How can I reduce high CPU usage in a PLC?

Simplify program logic, optimize I/O operations, reduce data logging frequency, and prioritize critical tasks to manage CPU load.

4. Can communication tasks impact CPU usage in PLCs?

Yes, excessive or inefficient communication tasks can strain the CPU, especially with high-frequency data exchanges.

5. What are best practices to prevent high CPU usage in PLCs?

Regularly update firmware, monitor CPU diagnostics, review code efficiency, and train staff on optimized programming techniques.

Conclusion

High CPU usage in PLCs can be a major bottleneck in industrial automation, leading to delays, system failures, and increased operational costs. By understanding the causes and implementing effective solutions, you can maintain a balanced CPU load and ensure efficient, reliable PLC performance. Remember, regular maintenance, monitoring, and optimization of programming logic can go a long way in preventing CPU-related issues, keeping your automation systems running smoothly for years to come.